Your data doesn’t expire — and neither does its value.

Velastra archives every reading, so you can run trend analyses, optimize lift strategies, and benchmark well performance across years, fields, or operators.

Whether you’re planning workovers or optimizing waterflood response, the insights are already flowing — straight from your wells to your screen.

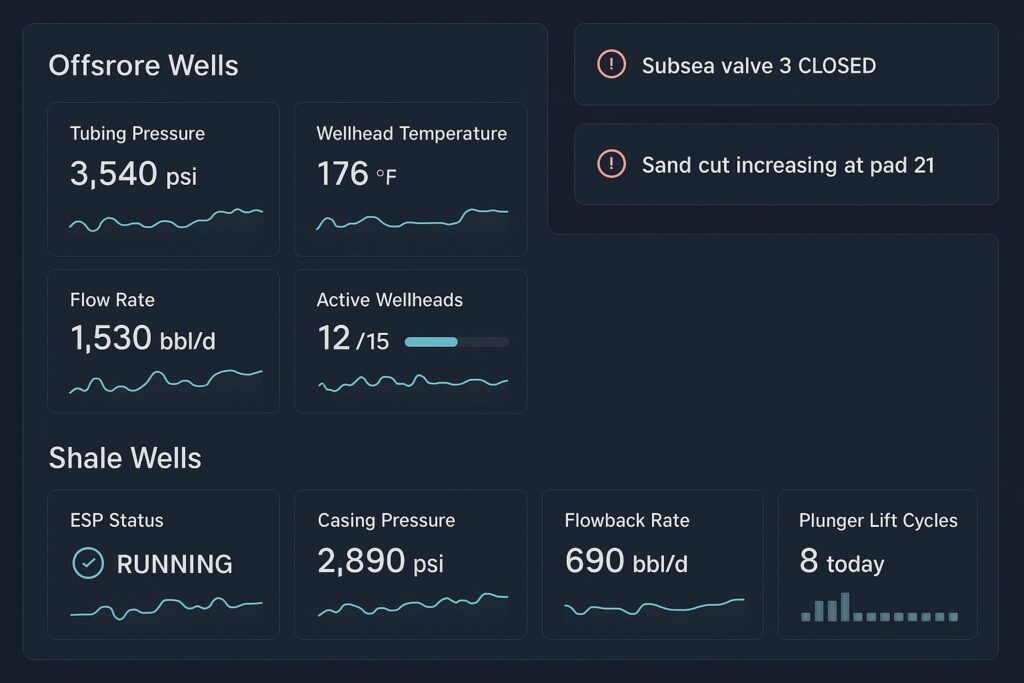

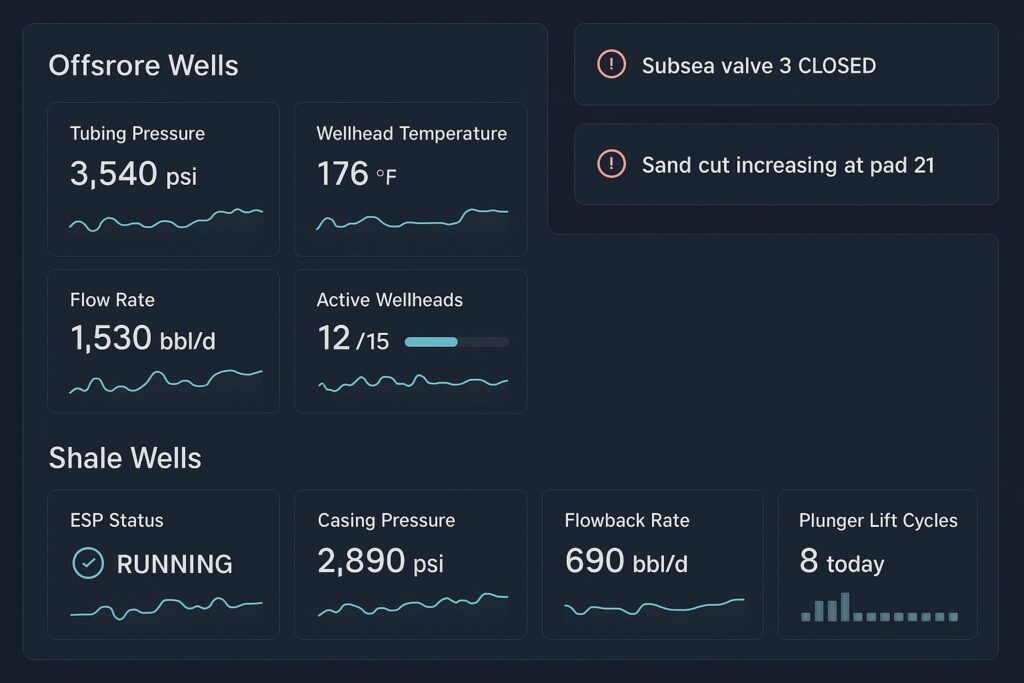

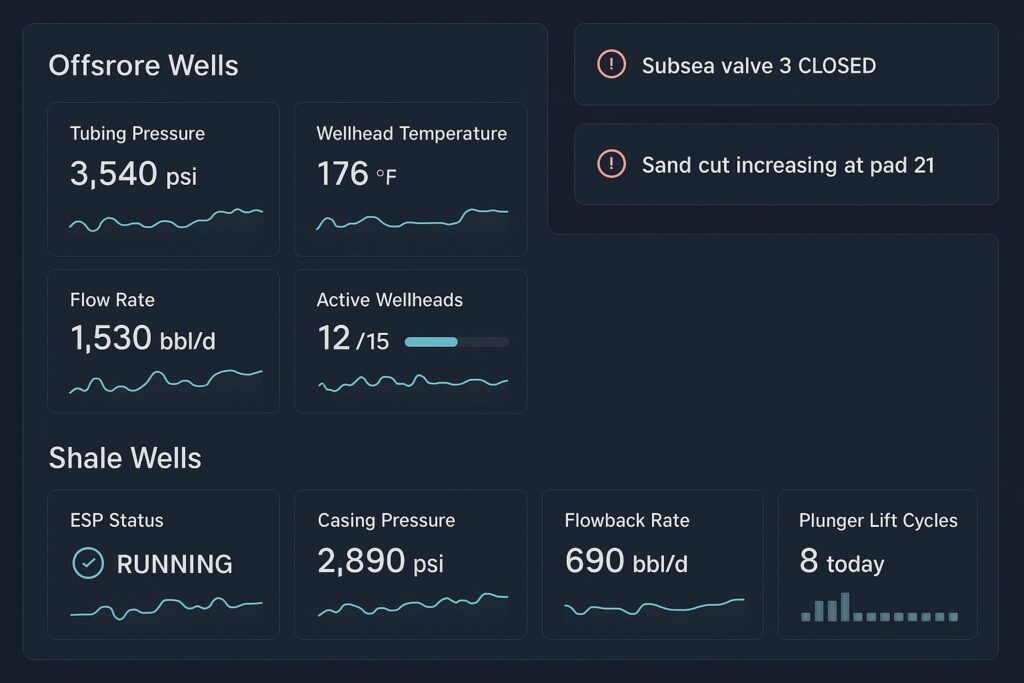

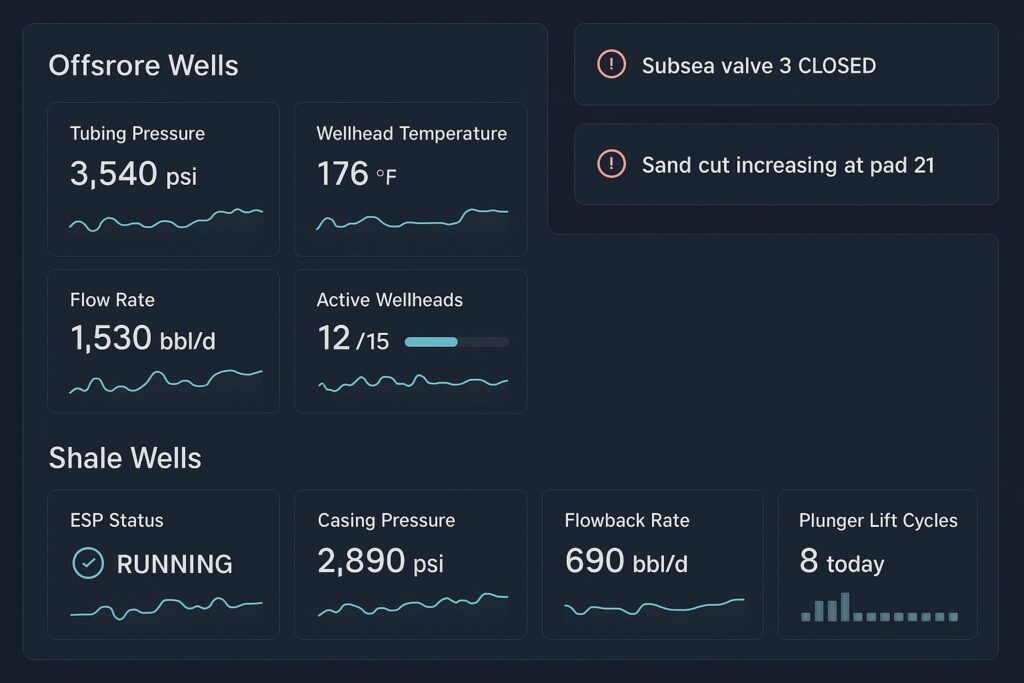

Operating offshore means dealing with distance, cost, and complexity. Velastra gives you 24/7 access to wellhead data without waiting for manual downloads or relying on unreliable comms.

From platforms to subsea tiebacks, our satellite-enabled gateways connect isolated wellheads — helping you reduce chopper runs, improve HSE, and optimize uptime.

even for subsea tiebacks Satellite + edge processing ensures continuous data relay without dependence on GSM, marine radio, or fiber backhaul.

(via annulus pressure trends & gas sensors) Early detection of casing pressure anomalies or gas buildup (methane/H₂S) allows containment before environmental or safety incidents occur.

Real-time visibility into compressor status, valve positions, and temperature/flow deviations enables predictive interventions and reduced production loss.

Remote monitoring of wellhead and subsea parameters eliminates the need for frequent site visits, saving $5,000–$20,000 per trip and lowering HSE exposure.

Shale wells decline fast — and missing even a few hours of performance data can cost thousands.

Velastra captures near-real-time data from every pad, even where there’s no cellular network.

From artificial lift status to frack flowback monitoring, your ops team gets a live feed to optimize every stage — from drill-out to production.

By detecting flowback and artificial lift anomalies in real-time, operators can respond within minutes vs. hours, preventing costly decline-related outages.

Missed alerts during early decline phases or frack flowback can lead to rapid well underperformance — real-time visibility helps avoid that.

even in off-grid or remote basins

Real-time pump status, tubing/casing pressure, and fluid levels allow operators to fine-tune lift parameters across multi-well operations.

With CO₂ injection, safety and precision are critical. Velastra helps you track injection rates, pressure buildup, and conformance — without daily field visits.

Whether you’re monitoring a pilot CCS site or optimizing waterflood performance, Velastra ensures your data is live, traceable, and accessible at any depth.

Ensures controlled pressurization, avoiding reservoir fracturing and maintaining conformance across target zones.

Real-time feedback allows automated or remote adjustments to injection volumes based on near-wellbore response.

Continuous downhole pressure and rate data accelerate decision-making on sweep efficiency, breakthrough risk, and zonal targeting.

even in GSM/fiber blackouts, Velastra’s edge + satellite mesh ensures uninterrupted connectivity from deep injection zones or remote pilot CCS sites.

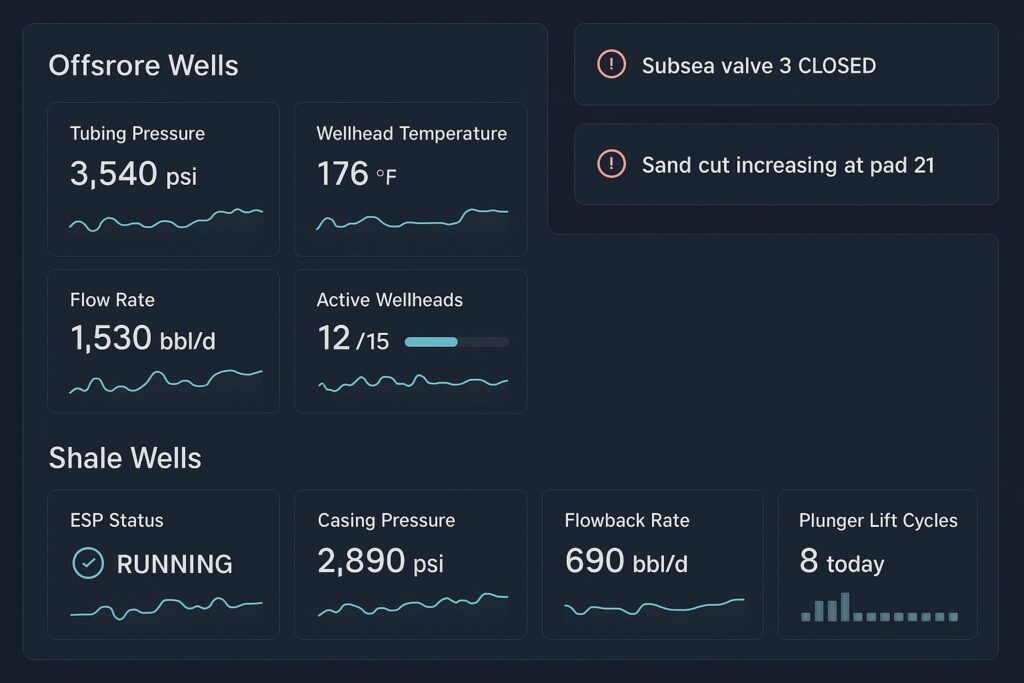

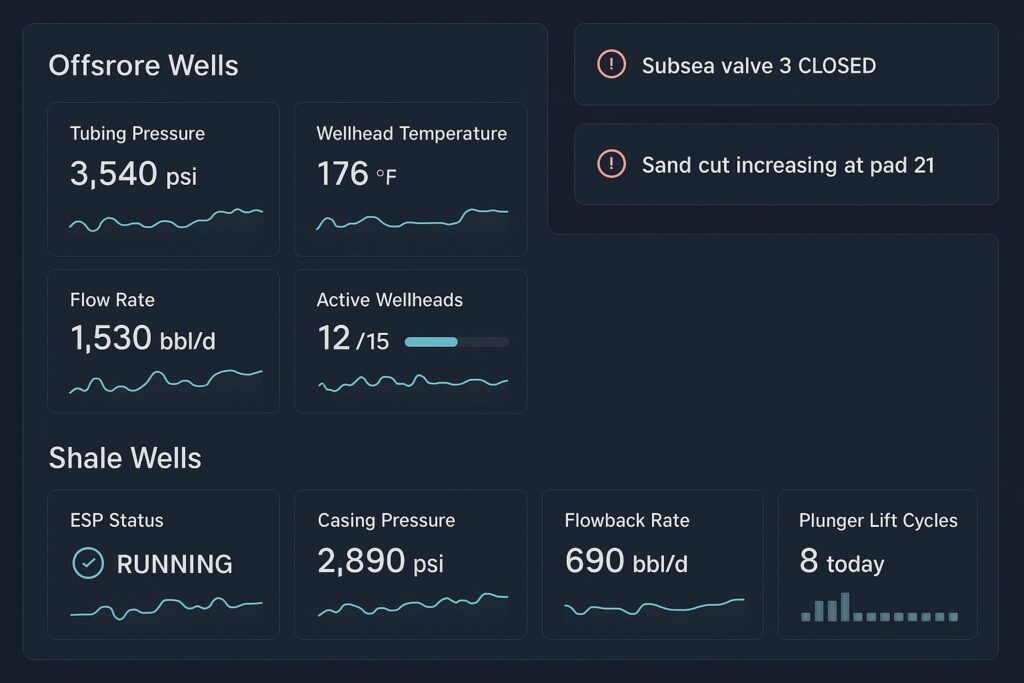

Operating offshore means dealing with distance, cost, and complexity. Velastra gives you 24/7 access to wellhead data without waiting for manual downloads or relying on unreliable comms.

From platforms to subsea tiebacks, our satellite-enabled gateways connect isolated wellheads — helping you reduce chopper runs, improve HSE, and optimize uptime.

even for subsea tiebacks Satellite + edge processing ensures continuous data relay without dependence on GSM, marine radio, or fiber backhaul.

(via annulus pressure trends & gas sensors) Early detection of casing pressure anomalies or gas buildup (methane/H₂S) allows containment before environmental or safety incidents occur.

Real-time visibility into compressor status, valve positions, and temperature/flow deviations enables predictive interventions and reduced production loss.

Remote monitoring of wellhead and subsea parameters eliminates the need for frequent site visits, saving $5,000–$20,000 per trip and lowering HSE exposure.

Shale wells decline fast — and missing even a few hours of performance data can cost thousands.

Velastra captures near-real-time data from every pad, even where there’s no cellular network.

From artificial lift status to frack flowback monitoring, your ops team gets a live feed to optimize every stage — from drill-out to production.

By detecting flowback and artificial lift anomalies in real-time, operators can respond within minutes vs. hours, preventing costly decline-related outages.

Missed alerts during early decline phases or frack flowback can lead to rapid well underperformance — real-time visibility helps avoid that.

even in off-grid or remote basins

Real-time pump status, tubing/casing pressure, and fluid levels allow operators to fine-tune lift parameters across multi-well operations.

With CO₂ injection, safety and precision are critical. Velastra helps you track injection rates, pressure buildup, and conformance — without daily field visits.

Whether you’re monitoring a pilot CCS site or optimizing waterflood performance, Velastra ensures your data is live, traceable, and accessible at any depth.

Ensures controlled pressurization, avoiding reservoir fracturing and maintaining conformance across target zones.

Real-time feedback allows automated or remote adjustments to injection volumes based on near-wellbore response.

Continuous downhole pressure and rate data accelerate decision-making on sweep efficiency, breakthrough risk, and zonal targeting.

even in GSM/fiber blackouts, Velastra’s edge + satellite mesh ensures uninterrupted connectivity from deep injection zones or remote pilot CCS sites.

Velastra-enabled FoG detectors complement geophone-based systems by capturing and transmitting data from localized rockfalls, small seismic shifts, or microbursts — even in areas where traditional comms don’t reach.

Our plug-and-play gateway ensures that every signal — no matter how subtle — is transmitted in real time via LoRa, Bluetooth, or satellite uplink, enabling early warnings and faster evacuation or response protocols.

By bringing edge intelligence underground, Velastra helps protect your people, assets, and productivity.

Measurable Impact:

Reduced unplanned mine stoppages by up to 35% and improved early-warning response times by 50% through real-time detection of micro-seismic events, even in deep zones without existing communication infrastructure. Resulted in fewer injuries, safer evacuation, and protection of high-value equipment.

In underground mining, ventilation accounts for up to 40% of total energy use, making it one of the largest operational expenses — and a major source of CO₂ emissions.

Velastra enables smarter ventilation through a plug-and-play IoT sensor network that monitors:

Our system transmits real-time data via mesh or satellite — no matter how deep or remote — allowing your control center to optimize airflow dynamically.

Industry Impact: