VELASTRA has everything you need to start. The solution includes hardware, oil and gas field service software, and the connectivity you need to connect the two. It’s easy to install (seriously, you’ll be up and running in two hours), easy to use.

Whether you’ve got gathering and transmissions pipelines with awkward geometry, or your lines are too remote to be monitored by cellular. We here to help you get clear, simple data from your pipelines to help optimise pigging and flow, at an affordable price.

Velastra delivers continuous, reliable data from the most remote pipelines — 24/7.

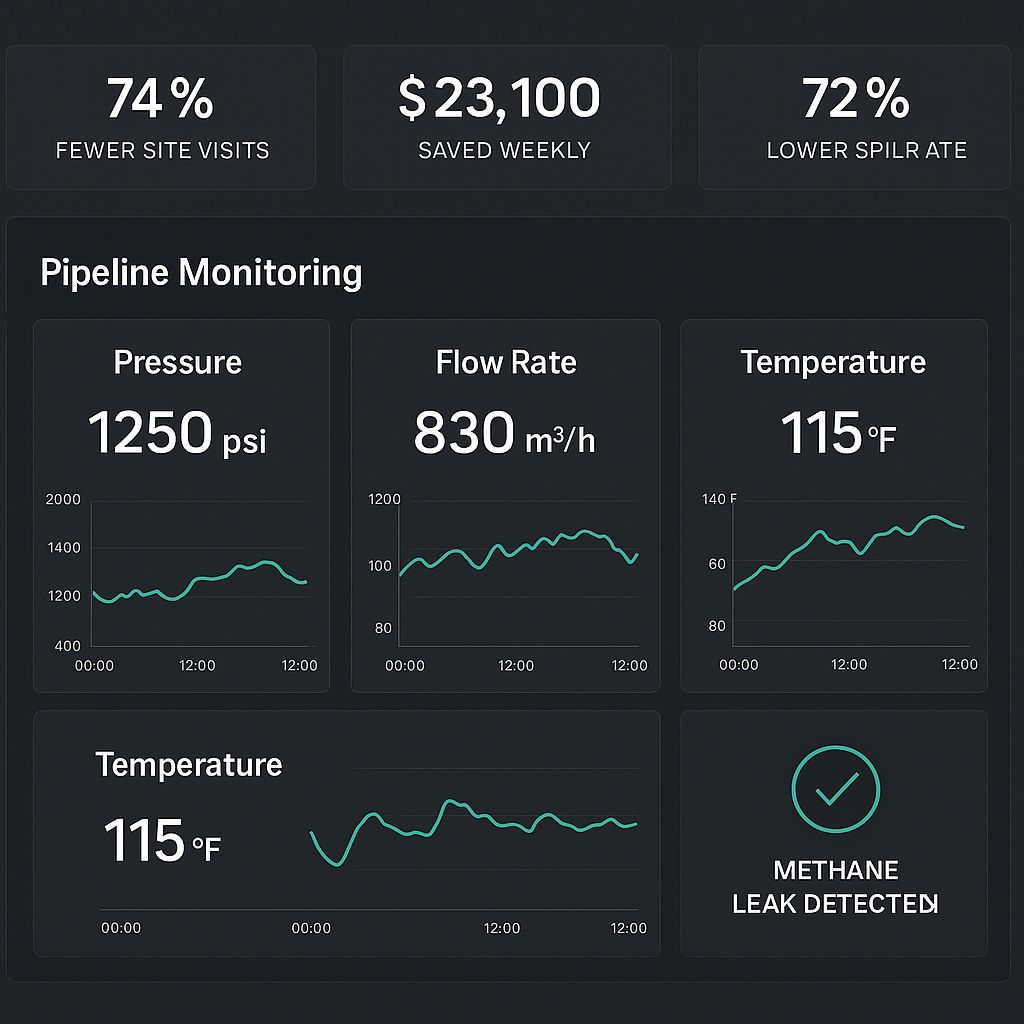

Track pressure, temperature, flow, vibration, valve states, and compressor performance without relying on fiber, GSM, or frequent site visits.

With optional gas detection for methane or other volatile compounds, you gain the visibility needed to prevent risks before they escalate.

Reduces operational downtime, through predictive maintenance

Reduction in manual inspection costs by eliminating routine site visits

hybrid connectivity ensures continuous data delivery even from regions with 0% cellular coverage — deserts, offshore lines, or jungle corridors

By continuously monitoring flow rate and compressor efficiency, operators can fine-tune parameters in real-time, resulting in higher system throughput and energy savings.

Velastra transforms isolated pipelines into live data streams. With real-time insights across pressure, flow, and gas leaks, teams can automate compliance, prioritize maintenance, and manage operations from a single centralized dashboard — even in GSM blackspots.

even in GSM/fiber blackspots, with satellite +

with built-in logs for OGMP 2.0, EPA LDAR, and PRS pipeline

via early gas leak detection (methane, VOCs) and automatic alerts

from 6–12 hours to under 30 minutes

Velastra’s edge gateway and sensor mesh continuously monitor pressure variations across pipeline segments — providing early warnings of buildup, sediment, or flow restrictions.

Optimize pigging schedules, target cleaning efforts, and keep throughput high — without relying on guesswork.

Optimization in pigging cycles by reducing unnecessary cleaning runs and associated operational costs

Savings depending on pipe length, terrain, and cleaning method

Redcution in unplanned maintenance, thanks to targeted intervention instead of blanket flush-outs

Alerts triggered for pressure trend anomalies, allowing same-day response